As a wave of Cabernet Sauvignon came in from our Rutherford property, Winston Hill, in mid-October, the Frank Family winemaking team was excited to put a new tool to use. The winery has recently made a sizable investment in the latest winemaking technology, an optical laser sorting machine.

This revolutionary upgrade allows only the finest fruit to reach our fermentation tanks, oak barrels, and ultimately our bottles. The term ‘optical’ is used because a digital camera takes pictures of the berries as they move across a conveying table and scans based on a pixel comparison of our perfect fruit.

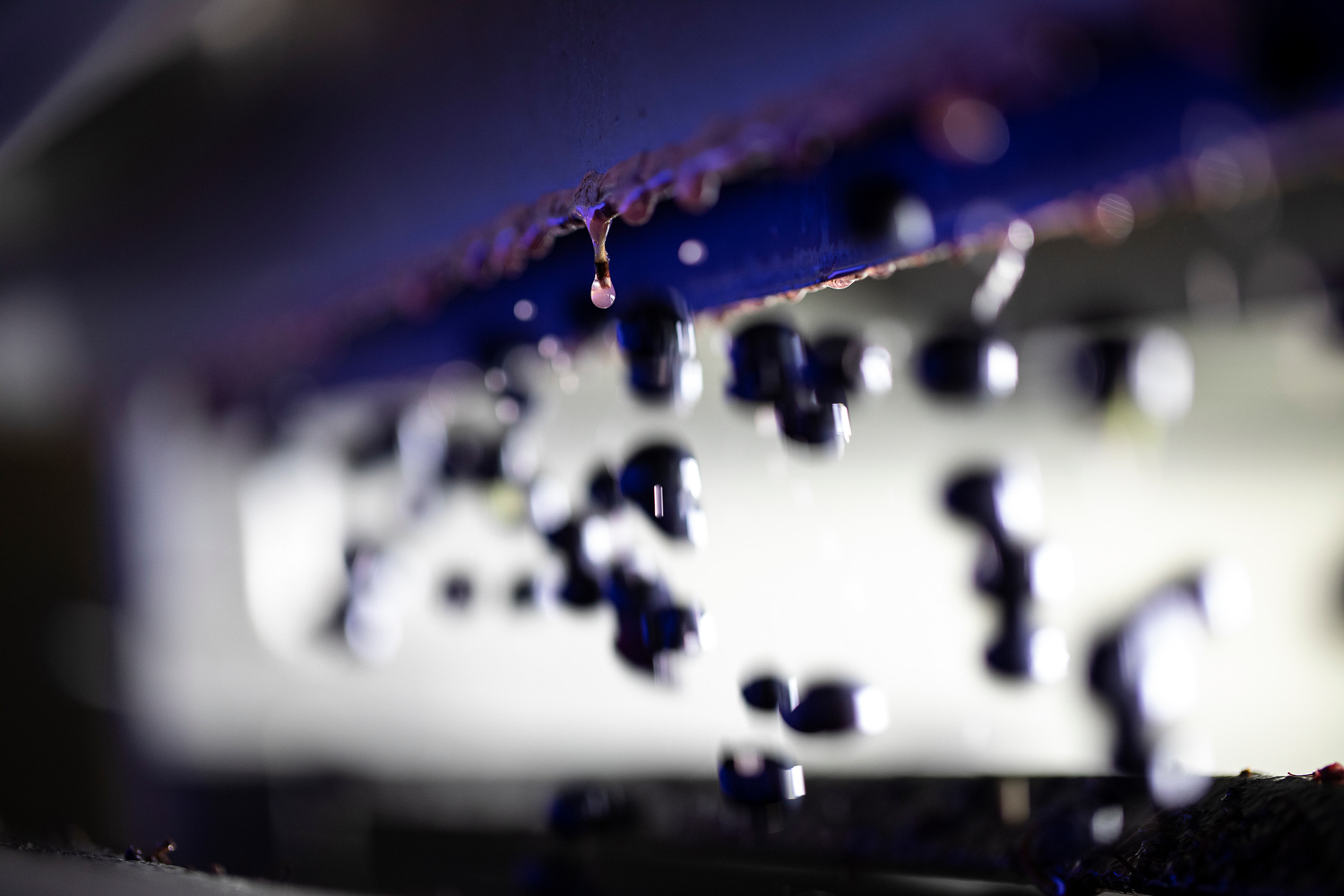

Each morning, as fresh-picked fruit is delivered to the crush pad, our winemakers carefully select our ideal berries and pass them through a stream of electroluminescent diodes, similar to LED lights. The machine reads the organic composition of each berry by taking a microsecond photo that measures size, shape, color, and organic structure. With the picture of the perfect berry in mind, the optical sorter will scan every grape that comes across the conveyer belt, analyzing each one with light waves at an incredibly rapid rate. In just 30 milliseconds, the digital scanner compares each berry against our winemaker’s exact specifications.

Fruit that is not worthy of our wine is removed from the group so that it cannot continue in the winemaking process. The optical sensor blows a strong blast of compressed air on any flawed berry, pushing it into a separate hopper. It’s really amazing to watch this machine in action – rejecting inferior fruit with unprecedented accuracy and collecting only pristine berries. We are beyond excited to add our optical sorter to the winery’s growing technological toolkit and watch as it continues to elevate Frank Family wines!